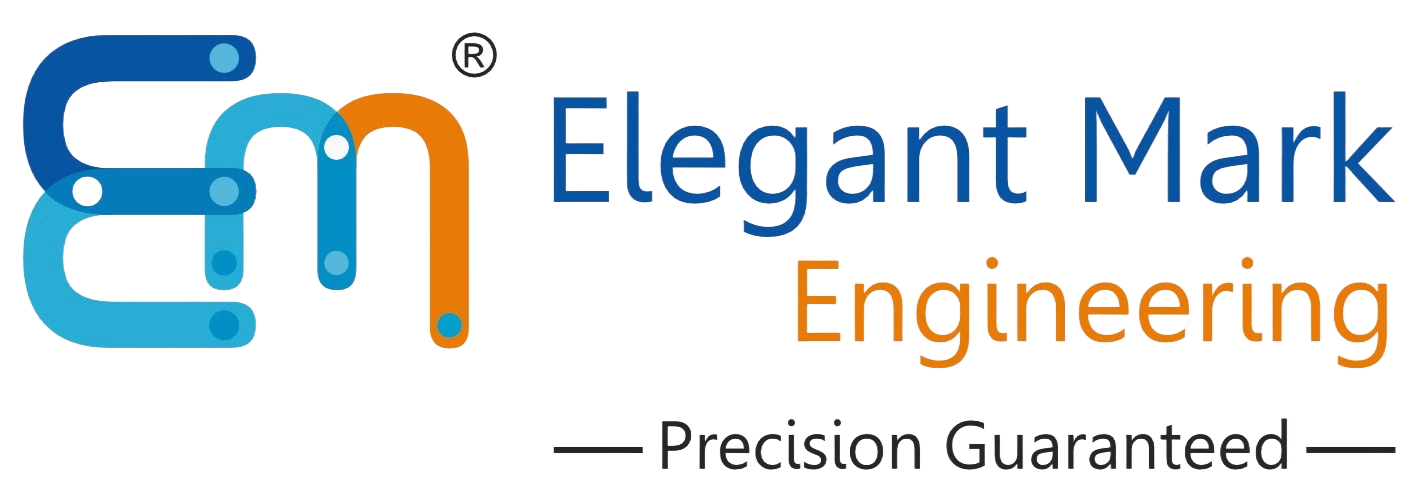

Trusted Engineering Excellence Since 1990

Established in Mumbai in 1990 as Shree Ganesh Engineering and later rebranded as Elegant Mark Engineering, we are an ISO 9001:2015 certified manufacturer serving the global market with precision-engineered machinery and spare parts.

Our expertise covers Plastic Molding Machinery, Blow Molding Spare Parts, and Ball Pen Refill Extrusion Machines, along with components like Screw Barrels, Nozzle Housings, Ring Plungers, and Tie Bars. With over 29 years of innovation and experience, we provide customized solutions, reliable repairs, and offshore consultancy services that ensure lasting value for our clients.

Advanced Extrusion Machinery for Every Application

Single Screw Barrel

Designed for smooth plasticizing and consistent extrusion performance.

Conical Twin Screw Barrel

Optimized for high torque and efficient compounding applications.

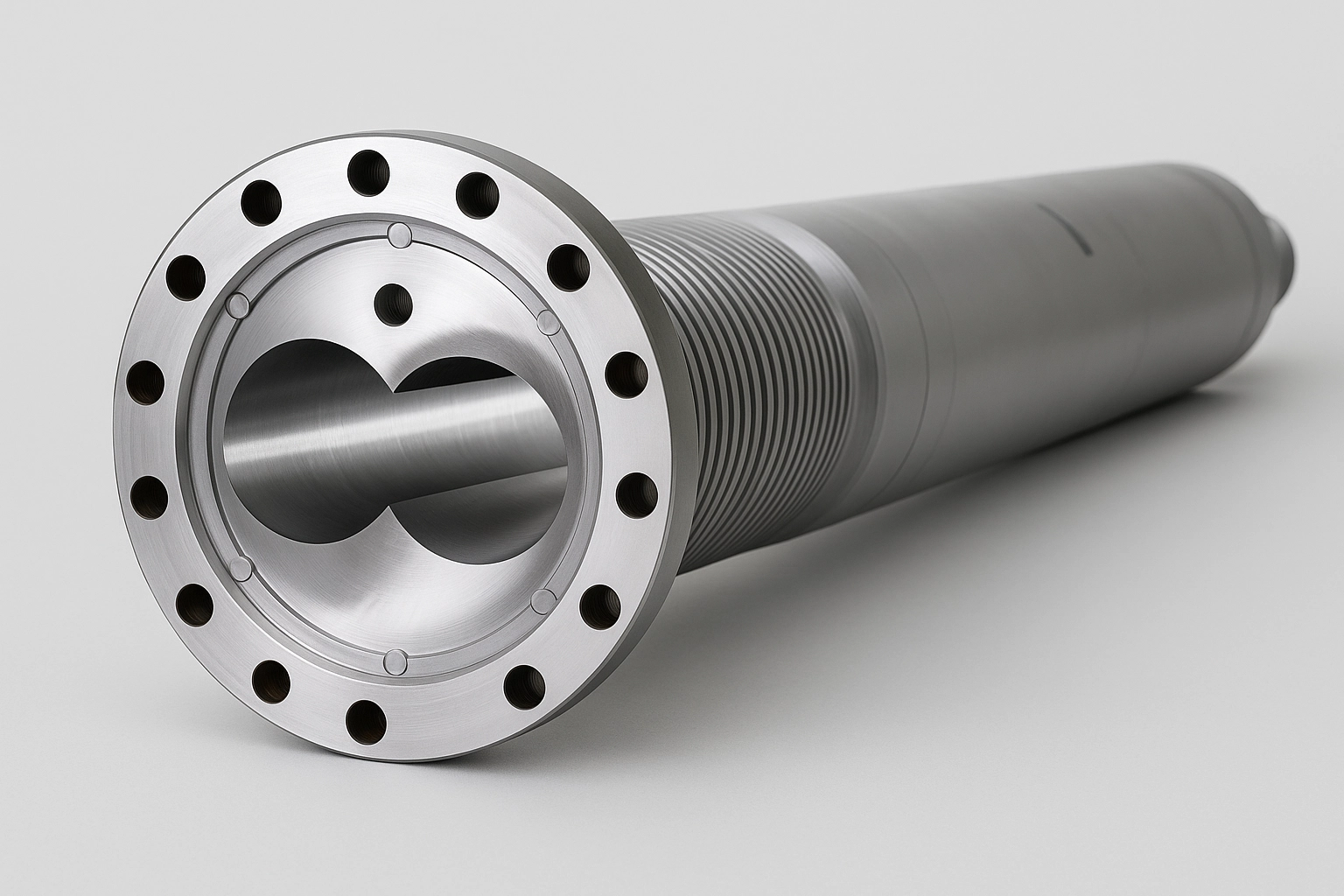

Parallel Twin Screw Barrel

Provides superior torque, mixing stability, and output consistency.

Segmented Twin Screw Barrel

Modular segments for flexibility and easy replacement during service.

Precision Molding Solutions for Every Industry

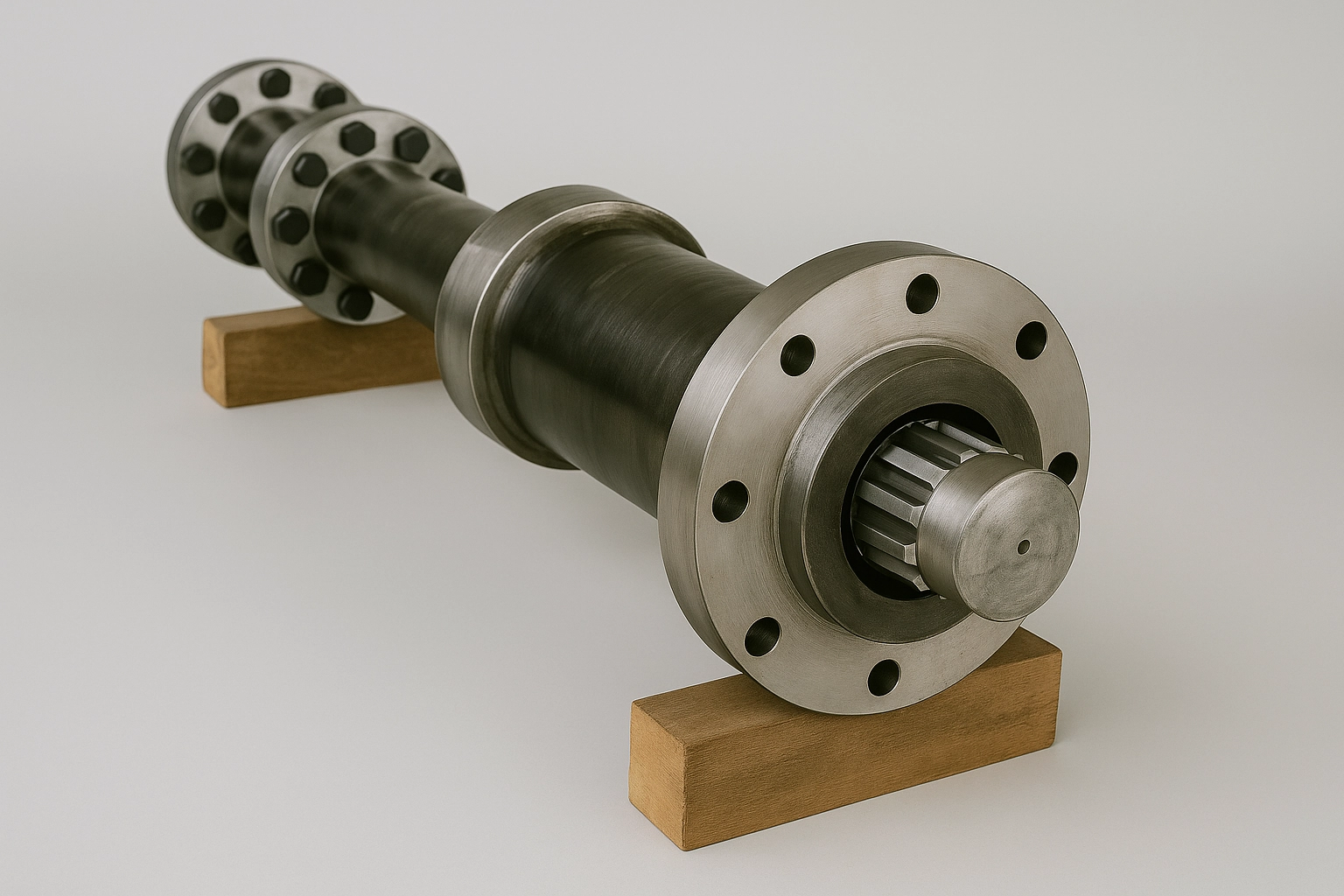

Injection Molding Screw Barrel

Precision-engineered for high efficiency and uniform melt quality.

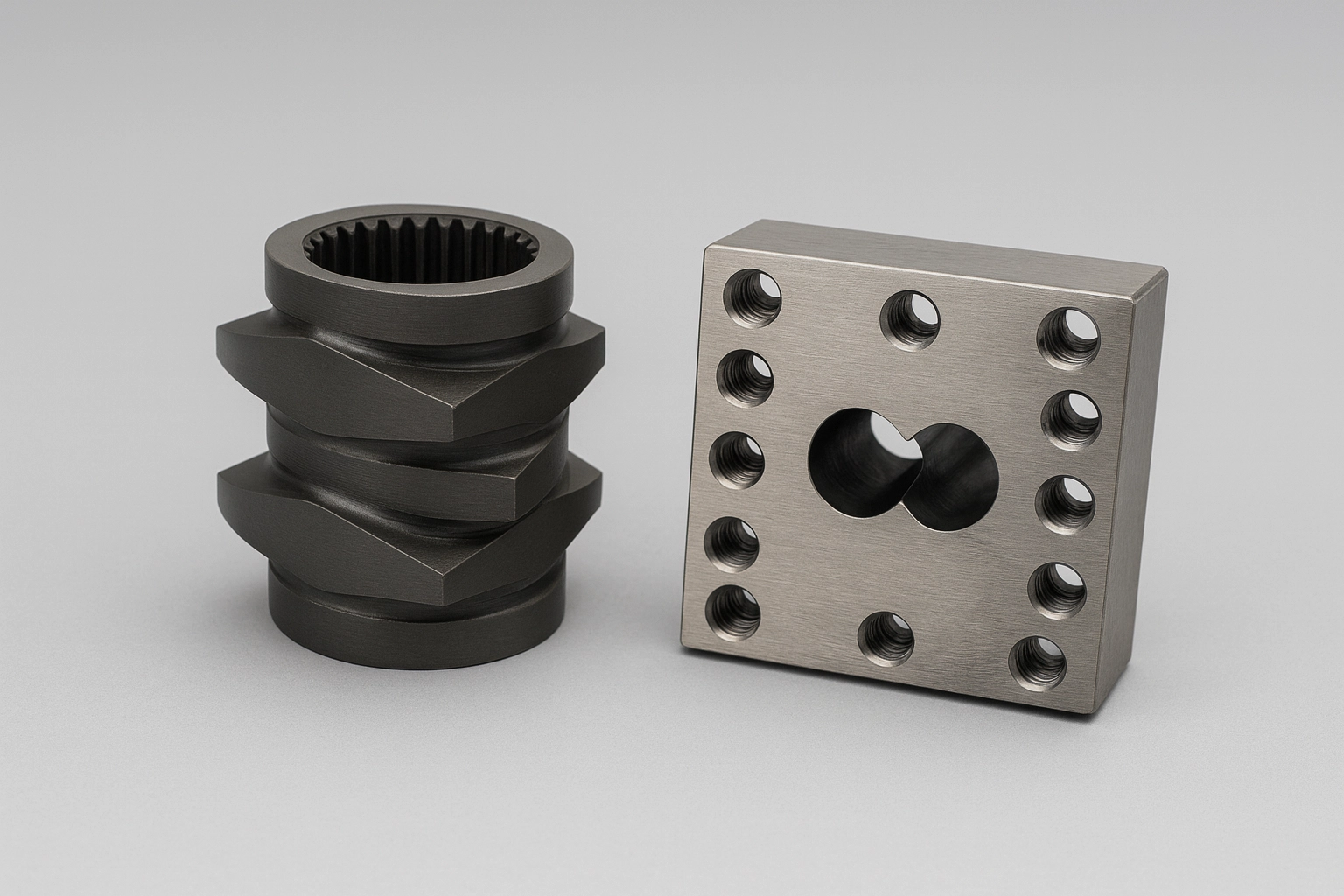

Ring Plunger Set

Ensures tight sealing and stable injection pressure for quality molding.

Excellence That Delivers Results

Engineered for Every Industry

Pet Bottles

Electrical & Switches

Household Plastic Furniture

Medical / Pharma

Consumables

PVC Pipes & Fittings

Packaging

Automobile & Rubber Tyre Industry

Home Appliances

Best Manufacturing Service Provider

At the core of the engineering industry, we deliver high-performance Plastic Molding Machinery, Blow Molding Spare Parts, and Ball Pen Refill Extrusion Machines with precision and reliability since 1990.

Always Committed to Quality & Innovation

From advanced screws, barrels, and carbide-coated solutions to complete extrusion plants, we ensure durable, efficient, and innovative machinery that drives industrial growth.

Experienced & Trusted Engineering Partner

With 29+ years of expertise and ISO 9001:2015 certification, we are recognized for excellence, timely service, and building long-term trust with global clients.

Your Gateway to Industry Insights, Technology, and Expertise

Powering the Future of Manufacturing

Stay updated with the latest trends, techniques, and innovations shaping modern manufacturing. From raw materials to finished goods, gain practical knowledge that helps optimize processes and boost efficiency.

Reliable Solutions for Every Industry

Explore advancements in industrial machinery and spare parts that keep operations running smoothly. Learn about durable components, smart upgrades, and cost-effective solutions to minimize downtime and maximize productivity.

Precision in Every Stroke

Discover the science and engineering behind ball pen refills. From ink formulations to production methods, get insights into technologies that deliver smoother writing, longer durability, and consistent performance.

Protecting Surfaces, Enhancing Performance

Dive into the world of industrial coatings designed to safeguard machinery, infrastructure, and products. Understand their role in durability, corrosion resistance, and efficiency across diverse applications.

Extending the Life of Assets

Learn proven methods for effective repair and preventive maintenance. From troubleshooting to best practices, discover strategies that reduce breakdowns, improve reliability, and save operational costs.

Building Trust Through Compliance

Stay informed about key international standards and certifications driving global trade. Understand compliance requirements, quality benchmarks, and the certifications that open doors to worldwide markets.

Our Manufacturing Process

STEP 01

Raw Material Selection

STEP 02

Forging & Rough Machining

STEP 03

Deep Hole Drilling & Gun Drilling

STEP 04

Grinding & Honing

STEP 05

Heat Treatment & Hardening

STEP 06

Precision Machining

STEP 07

Polishing Process

STEP 08

Surface Coatings & Cladding

STEP 09

Quality Inspection & Testing

STEP 10

Final Assembly & Dispatch

At Elegant Mark Engineering, we don’t just manufacture screw barrels, we engineer solutions that power industries, extend machine life, and drive growth for our customers.

Customers Sharing Experience - Must Read

Everything You Need to Know at a Glance

Article & blog posts wih useful information

Engineering Solutions for Industries and Factories

We're Certified Company

ISO 9001:2015 certified, delivering globally trusted machinery and spare parts since 1990.

We Deliver Reliable Engineering Services

Our team ensures precise installation, maintenance, and on-site support for all industrial equipment.

24/7 Technical Assistance

Round-the-clock service to keep your machines running without interruption.

Ask Us a Question…

Have a query about our machines, spare parts, or services? We’re here to help you with the right solutions.